Author: adwizard

The pictures below are the Topper I made for my dining room. The inserts (there are six per set) are magnetically held in. It was designed to change out for the season or event. Notice the backside hole to put a finger through to pop the section loose from the magnet for a change-out. We are starting out with four sets and see where it goes.

The center Hummingbird is also a change-out. I have our initials to sub out for the Hummingbird.

As of these pictures, there is no finish on it yet. Stay tuned for pictures of the oak rod to be stained with a dark finish.

[slickr-flickr search=”sets” set=”72157700054823634″ items=”50″ align=”center” type=”gallery”]

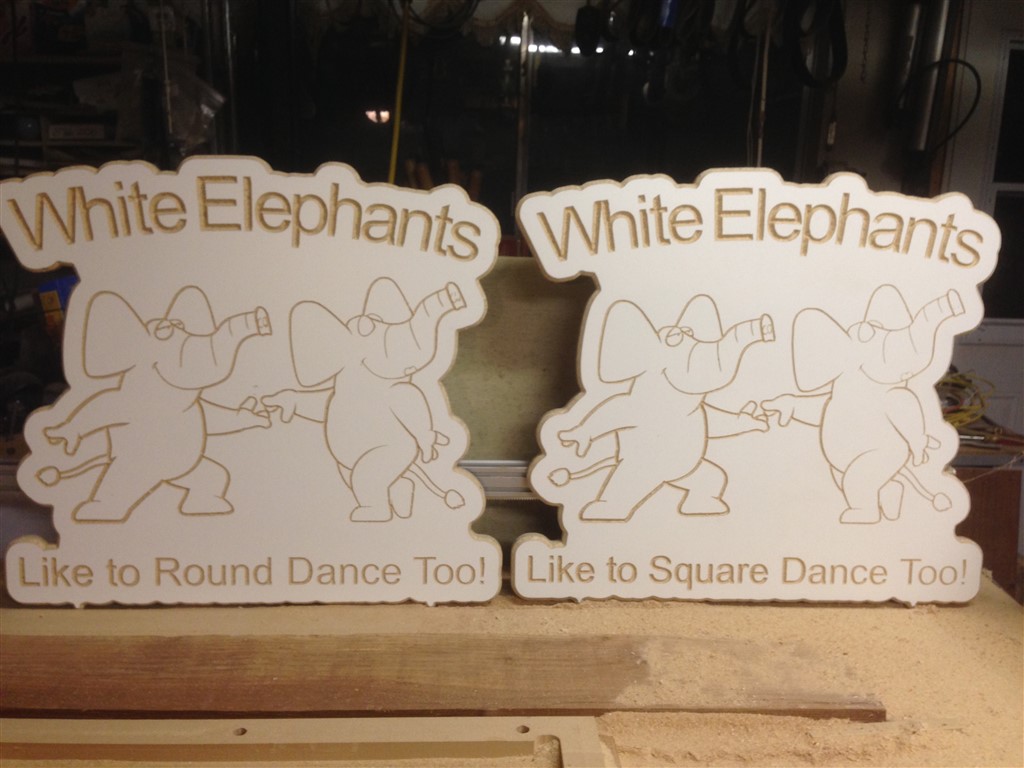

Every year at the local Callers Association in Oakdale, we have a Christmas dinner. Our main planned activity aside from the dinner is the traditional White Elephant gift exchange.

I like to offer white elephant gifts… Literally!

Actual 3D cutting. Usually, a ball nose bit is used with a fractional step-over per pass to achieve an even surface of cut in the Z axis.

As a rule, this is done with a 3-axis machine. The limitation is that Z is only Vertical.

A 5-axis machine (normally seen as a large arm that articulates in five directions. These are normally referred to as robotic arms. Click here for a you-tube search for robotic arms to see some examples. Normally the Z can come from almost any direction including from the bottom up. i.e. A cut under a wooden rose petal to give it even more of a 3d appearance.